HOW TO CREATE A PREVENTIVE ELECTRICAL MAINTENANCE PLAN

This happens for many reasons, but the reality is that asset management programs must be applied equally in the electrical and mechanical parts.

Signs that maintenance strategy changes need to be made

The days of inactivity and unemployment are not included in the calendar.

Few electrical tasks are documented.

Spare parts are not where they should be.

There are few people in charge of electrical maintenance .

There are no standards for electrical diagrams, so you have to improvise.

The corrective maintenance is the main strategy to respect.

There is no plan related to the operational safety of the equipment.

Many electricians have lagged technologically.

If most of these have been present, then it is time to get to work.

Steps to create an electrical maintenance plan

Here are the steps to create an effective electrical maintenance plan:

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

1. Recognize the current situation

It is necessary to accept that a change is required to improve things. Only then will the relevant measures be taken.

2. Develop a vision for the electrical maintenance program

What do you want? Here are some examples:

The most important equipment will have maintenance strategies developed in a maximum of 12 months.

The less important equipment will have maintenance strategies developed in a maximum of 24 months.

An update of the electrical diagram management will be implemented in the next 12 months.

Days of inactivity will be established for electrical equipment.

3. Get support from an electrical task force

It is necessary to share the plans with this group, as they are the ones who know the plant perfectly. Their ideas must be included in the vision so that members feel included.

4. Get support from management

If management does not support the vision, there is very little chance of success. For this reason, it must have enough arguments to be taken into account. The benefits should be highlighted, as well as the future earnings. Questions will abound, but if the proposal is strong, then there will be no problem.

The vision should make it clear that several resources will be required to obtain significant improvements when creating an electrical maintenance plan.

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

This does not necessarily mean that more people are needed. Getting help from third parties usually makes the most sense. When the program goes live, the gain in efficiency will compensate for the absence of a few workers.

6. Understand the importance of electrical assets

A tool can do this job, but if assets have already been with the company for some time, employees will be the ones with the best view of their status. The most important assets will be the starting point.

7. Create a fault history

There are two areas in which this information can be found: computer-aided maintenance management and operator experience. The goal is to understand the faults that need to be mitigated when creating an electrical maintenance plan.

8. Understand the potential causes of failures

For newer and larger assets, it is recommended to perform a failure mode and effect analysis or maintenance processes focused on reliability. These tools will identify what might go wrong and what would happen.

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

Thus, decisions can be made based on the most critical effects.

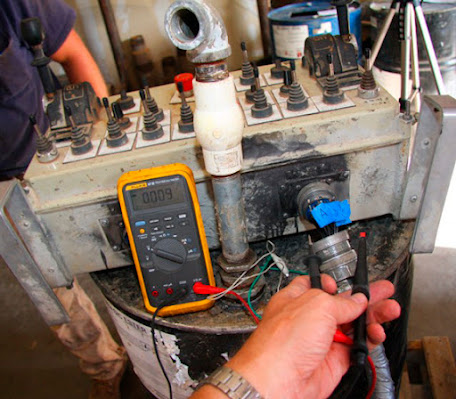

9. DDevelop preventive maintenance inspections to minimize known and postulated malfunction modes.

Before building the electrical maintenance plan, the existing one should be evaluated. If it hasn't been reviewed in a long time, you probably already have several shortcomings:

The actions developed in the new plan must be quantifiable.

The infrared thermography is the best option to detect hot spots in the control and distribution equipment.

For all electrical components, the “clean, cool and dry” rule is elementary to keeping technicians safe.

10. Ensure that all strategy documents have been captured and scheduled to run during downtime

These actions can take a long time, but must be done so that resources are available at all times. Failure to do so could be viewed in a bad light by customers.

11. Organize the material

For the planned work to be carried out properly, the materials must be arranged according to the hierarchy of the equipment, so that they can be identified and ordered appropriately. Critical equipment must remain for inventory, as not having it can have serious consequences if needed. All of this categorization should be part of the overall project.

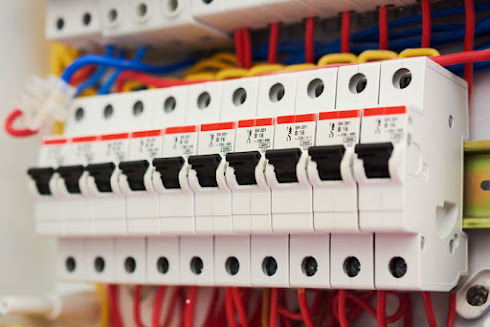

12. Manage electrical diagrams

A review of the accuracy of the electrical diagrams should be done in the order of importance of the equipment. The most experienced and trained personnel should participate in this activity. It is recommended to make digital copies of the diagrams to keep them within reach. This can be laborious, but the benefits will be enormous.

13. Train electrical personnel

Creating an electrical maintenance plan with all personnel will be essential to begin a training process. Generating a matrix that includes the specific technologies and skills required would be very helpful.

14. Make sure all processes are well documented

Prioritization is very important so as not to lose control. This should be based on urgency, business value, and time constraints.

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

A workflow model to achieve this must include the processes to deal with breakdowns, plan, perform scheduled tasks, and capture all movements in the system.

15. Get feedback

Feedback from staff will be critical to creating a truly effective electrical maintenance plan.

Comments

Post a Comment