THE IMPORTANCE OF MAINTENANCE OF ELECTRICAL SUBSTATIONS

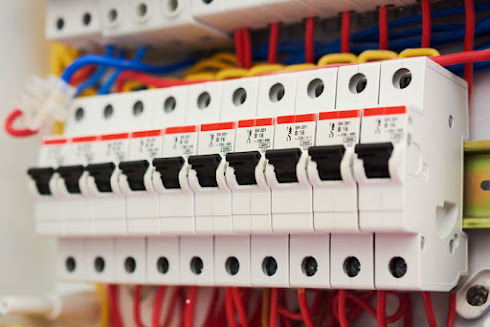

The electrical substations convert the energy of thousands of volts to manageable levels. Once transformation occurs, electricity can be safely channeled to homes, buildings, and other structures. To supply the adequate voltage, this installation needs to achieve a perfect interaction with all its components, especially with transformers, circuit breakers, and protection relays. Testing these items is essential to practice to ensure proper operation.

The maintenance of electrical substations allows the service to be interrupted as little as possible. Their main objective is that they only stop operating in a planned way to implement a preventive maintenance and cleaning program. Failure to do so will lead to unscheduled stoppages, costly repairs, and unanticipated tasks by staff that will begin to negatively impact a company's finances and operations.

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

A variety of problems can affect the performance and reliability of a substation. Finding potential failures can reduce the cost and difficulty of repairs.

Documentation and analysis

The information collected during each maintenance session is documented in order to have an accurate understanding of the status of the system. Later, these reports allow recognizing long-term failures and opportunities for improvement.

The technicians evaluated the substation components for accumulation of moisture, acidity, and solid particles. These pollutants usually have a negative impact on the operation of the electrical infrastructure.

Of course, all these works are carried out with all the security measures.

Maintenance

Many of the programs used by the power generation and distribution industry have become obsolete in recent times. For this reason, it is necessary, for example, to clean the high-voltage insulation

Since most transformers are several decades old, changing their paint to protect the coating from corrosion is a very important task. This prevents further damage and extends its life. The paint job in a substation also helps maintain other structures.

Substations should also be periodically upgraded to meet a possible increase in demand. If these are not planned, a lot of electricity could be moving through the system, compromising the equipment, causing blackouts, and reducing its reliability.

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

If the problem persists, the facility would be forced to respond to overloads with the technique known as load shedding or by cutting off a group of users in a distribution circuit to lower power to a level within the substation's capacity. The improvements alleviate the need for the above and allow for greater demand to be accommodated.

Generally, a maintenance program for electrical substations is made up of:

Testing and calibration.

Inspection.

Settings.

Cleaning.

Repairs.

Analysis of insulating liquids.

A report that lists the deficiencies found and that are recommended to be repaired is also usually included. The information collected is stored for future reference and is used to monitor the electrical performance of the system from year to year.

Phases

Generally, the maintenance of electrical substations is divided into primary and secondary tests:

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

Primary maintenance tests for electrical substations

Transformers and circuit breakers are some of the most important components in an electrical substation. Over time and their continued operation, they begin to wear out, which can only be prevented with maintenance.

Circuit breakers are analyzed during this phase to identify any possible abnormal operation. If any are found, they are subjected to preventive maintenance.

Some of the parameters are reviewed include the synchronization of the poles, coils condition, contact resistance, while opening and closing, etc.

Transformer tests are also carried out. Because these machines experience tremendous heat and other stresses, routine maintenance is required to ensure good performance.

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

This includes testing the winding resistance and voltage recovery, observing the polarization index, and measuring the short-circuit impedance.

Secondary maintenance tests for electrical substations

These are done to ensure that the protection scheme provides the expected level of performance. Injection tests are carried out at intervals to evaluate relays, windings, protection panels, and the performance of secondary equipment.

They may also include tests overcurrent, distance, frequency, and voltage protection, reclosing schemes, etc. This is separate from tests on the winding, load, polarity, and protection and control circuits.

State-of-the-art equipment allows evaluations, calibrations, adjustments, and cleaning where needed. As part of electrical substation maintenance, they can identify inefficiently or failed parts that require replacement through on-site repairs.

Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical Standford Electrical

Each device in a substation requires different strategies. Implementing the appropriate actions at the right time will define the procedures to be followed, based on the conditions, reliability, and times.

A good plan of this nature ensures reliable distribution and reduction of failures. Many of these can be detected during routine maintenance, reducing the risk of downtime and preventing future problems.

Comments

Post a Comment